CNC Machining Is More Than a Secondary Operation for Laser Precision

September 26, 2019

CNC machining has been a vital element of our success since we integrated it into our business. While our reputation has been built on being a full-service sheet metal and plate fabricator, we can also do pretty much anything that can be done on a vertical mill.

How did this capability come about? We provide a broad range of custom fabrications in a wide assortment of shapes and sizes. These workpieces have design requirements that need to be held consistently and accurately as they are being worked. There are times in which tolerances need to be held so tight, we need to do this in a machining center.

The Right Equipment for Each Job

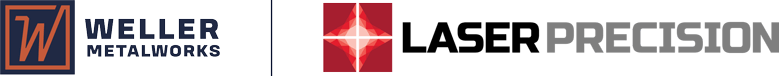

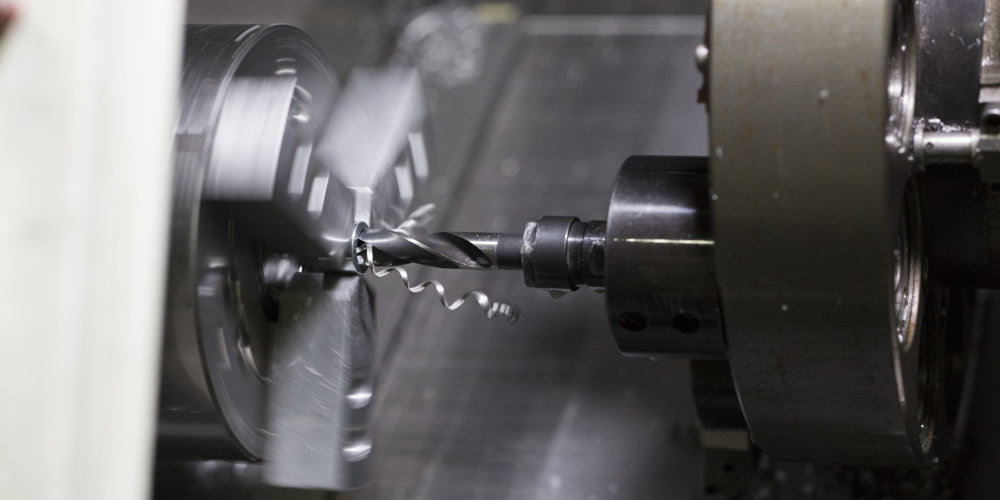

We don’t just have a small toolroom tucked away in the corner of the shop. If you walk through our plant, along with the lasers, press brakes and welding equipment, you will find vertical machining centers of various travels to accommodate different size workpieces, a gantry style router and several turning centers. (See a complete list on our website.) With this wide range of equipment, we have machining capabilities that range from the extremely simple to awesomely complex:

- Milling and contouring

- Precision drilling and tapping

- Facing and profiling

- Engraving for traceability

- Counterboring and countersinking

Complete Control

The ability to handle CNC machining jobs in-house gives us much more control over the process. We have the right equipment. We know our operators are properly trained in print reading, programming and set up. We know how high our standards are which is why we elect to keep the operation in house. Why spend time checking someone else’s work when we already know the quality of ours? All your machining needs can be met in a timely fashion without adding shipping charges back and forthto outside vendors.

Lower Costs

Speaking of expenses, our digital design CAD/CAM program cuts a lot of cost from each job. A program that could take hours to plot by hand can be done in ten minutes and saved into a data archive.Once they are written, programs are saved and used for future jobs.That means we can produce consistent machined parts very quickly without setting every job up from scratch.Labor costs and the risk of human error are also reduced; the operator downloads the program to the CNC, sets up the correct fixturing and runs the job.

Consistency and Quality

CNC machines can also size to print with consistency day in and day out over a large quantity of parts. This allows us to hold extremely tight tolerances (plus or minus 0.0005”). To make sure the parts meet spec, our standard practice is to check the setup piece, middle piece, and last piece of each run. Tolerances are tested with a variety of measurement devices including micrometers that go to the third decimal place (in metric), height gauges, indicators and CMM (computer measuring machines) as well.

For a complete run-down on our metal fabrication capabilities, check out our web site or contact us and we’ll walk you through it. Whatever your fabrication need is, our goal is to give you a feeling of confidence with every delivery.