Importance of Robust Supply Chains in the USA and Procuring Subcomponents Near You

February 07, 2022

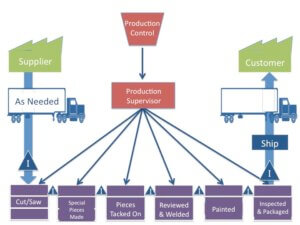

A supply chain is a network between a company and its suppliers to produce and distribute a  specific product to the final buyer. It encompasses the steps it takes to get the productor service from its original state to the customer. The Great Disruption: why the supply chain fell apart, and how manufacturers can respond.

specific product to the final buyer. It encompasses the steps it takes to get the productor service from its original state to the customer. The Great Disruption: why the supply chain fell apart, and how manufacturers can respond.

Photo Credit: Griffin & Co, Figure 1: Floor Plan & Supply Chain for Manufacturing Industry

2019: The onset of The Great Disruption

COVID-19 was the perfect black swan to put pressure on these complex supply chains. Breakdowns began as small, seemingly insignificant entities lost the ability to produce components and fill orders for value streams. This in turn caused breakdowns at higher-level component suppliers as the failures of their suppliers caused their lines to shut down.

In the end, containers that were destined for our ports didn’t ship, products didn’t deliver and shelves went empty. This created secondary issues, causing financial stress and inevitable increases in inflation as scarcity was offset by rising prices. Downstream effects also included scarcity in raw materials, including energy and further pressures on prices, as these component elements rapidly increased in price.

Early on in the supply crunch, the greatest toll was not in the availability of product, but rather the lack of visibility of the supply chain itself. The supply chain simply went dark, and no one knew when, or if, the components they needed to build their products would arrive. No one could effectively plan as supply chains fell victim to varying degrees of governmental restrictions, public health shutdowns, virus outbreaks and logistical delays.

Early on in the supply crunch, the greatest toll was not in the availability of product, but rather the lack of visibility of the supply chain itself. The supply chain simply went dark, and no one knew when, or if, the components they needed to build their products would arrive. No one could effectively plan as supply chains fell victim to varying degrees of governmental restrictions, public health shutdowns, virus outbreaks and logistical delays.

Today, despite a broad re-opening of commerce, the complications within the supply chain have worsened. The fundamental causes are myriad, however, suffice to say governments, central banks and large multinational corporations have failed to recognize the complexity and fragility of a demand-driven supply chain.

Well-intentioned efforts to mitigate the spread of the virus have cascaded into unintended consequences rippling throughout the macroeconomy. Resources have been misallocated or misdirected, labor markets have been artificially repressed. In addition, central banks and governments have engaged in progressively stronger methods to bring normalcy to the economy.

In the end, modern supply chains ended up being extraordinarily complex combinations of labor and materials, sourced from distant locations, visible only through an opaque lens of vendor associations and relationships. Is it any wonder that these complex systems failed when introduced to the stress of global disruptions and unexpected consequences?

Part 2: How to respond

This, of course, begs the question: how do we respond and overcome the current disruptions in global supply? Many large integrated manufacturers have taken the immediate step of shortening the supply chain, beginning the process of re-shoring components that may have previously been manufactured overseas. This provides several benefits:

- Allows greater visibility and reduces uncertainty regarding assurance of supply

- Reduces distance between the component manufacturer and the end user

- Eliminates steps in the logistics process

- Allows the integrated manufacturer to intervene and assist in difficult circumstances, providing a more manageable process for vendor surveillance and intervention

There is also a newfound interest in establishing domestic relationships with world-class suppliers who have the ability to effectively compete globally thanks to innovations in technology, data systems and process control.

At Laser Precision, we have maintained world-class performance for the entirety of the global pandemic. Our current performance metrics include:

At Laser Precision, we have maintained world-class performance for the entirety of the global pandemic. Our current performance metrics include:

- 92% On-Time Shipping across 3000 shipments per month

- A current PPM defect reject rate of 116 PPM

- Management of 10,000 discrete part numbers

- An industry 4.0 data management system, allowing bi-directional electronic collaboration

There is no doubt that industry will recover from the challenges of the past two years. While the damage to the supply chain has been severe, you can take the steps, right now, to mitigate the damage and return to predictable performance. At Laser Precision, we stand ready to help.