Quoting, Development, Execution: The Journey of Metal Fabricated Parts

May 17, 2023

To the uninitiated, a fabrication shop can seem to be rather chaotic. Press brakes are thumping, machine tools are whirring and forklifts are running up and down the aisles. But if you look carefully, you can begin to see that each movement is planned and calculated for maximum efficiency.

How do all these people know what they’re doing? The coordination doesn’t happen by accident. It takes a lot of thought and planning to take raw material, turn it into a functioning part and ship it to its destination.

Perhaps the easiest way to understand the process at Laser Precision is to follow a part as it moves through the three stages of fabrication: Quoting, Product Development and Execution. For our example, let’s select a bracket assembly.

STEP ONE: QUOTING

Everything starts when we receive an RFQ (Request For Quote) from the customer. It contains an EAU (Estimated Annual Usage), which is the quantity the customer expects us to deliver in a year’s time. From this, we can derive the raw material, laser capacity, machining time and all the other elements that go into the cost of the part.

Advanced Product Quality Planning

A preliminary review of the part, known as an APQP (Advanced Product Quality Planning), ensures that any and all quality and engineering requirements for the bracket assembly can, in fact, be completed by the software, machines and personnel in our plant. It also serves as a double check to make sure we can produce the parts to our customer’s exact requirements.

We use the APQP as an opportunity to work with the customer to align their design needs to our fabrication abilities. Simple revisions to the original print can often save money for the customer and decrease delivery times. If the customer can’t budge, we determine if we want to submit a bid for the part. We would never just take the work and hope for the best. If we can’t reliably quote it, we’re very honest about it.

Bill of Materials

The next step is the development of a BOM (Bill of Materials). This is essentially the recipe that includes any and all steps required to fabricate the bracket assembly. Things that would be included in the BOM are value-added operations and materials consumed in order to successfully manufacture the part.

In this stage, we take a careful look at the print provided by the customer. We can see that the bracket assembly consists of two pieces that must be laser cut and welded together. One section has a bend, so that press brake time will be needed. There are indicators for tapped holes, which will be a job for our machining department. A part ID number needs to be stamped on and the whole piece has to be painted.

After that, the bracket assembly is complete. So to recap: it starts with laser cutting and machining. Bending is next, followed by welding, stamping and painting. That’s the project.

Based on the BOM, the quote calculator comes up with a price, which we submit to the customer. That concludes the quoting process, and once a Purchase Order is received, we go on to product development.

STEP TWO: PRODUCT DEVELOPMENT

Production Part Approval Process

With a purchase order in hand, the next step is for our Quality Department to develop a PPAP (Production Part Approval Process). This document is a supplier’s manufacturing plan for a specific part, providing evidence that they will be able to successfully produce the part with the processes and controls they currently have in place.

This written assurance has become so effective at reducing unacceptable parts that major OEMs today require a PPAP before they will do business with a vendor. At Laser Precision, we’ve created thousands of PPAPs over the years, and we’ve seen the evidence pile up in that time: a solid PPAP regularly saves time, money and headaches down the road.

We believe in the acronym so strongly that we wrote an in-depth piece on it. You can read it here: PPAP Provides Evidence of Laser Precision Quality

Engineering

Working from the PPAP, our Engineering Department determines what the bracket assembly will look like. Generally, we’re provided with blueprints and 3D models, but sometimes we only get a sample of the piece to be made. In those rare instances, we have to reverse engineer the part, determining the processes and materials it will take to make an exact duplicate.

A drawing is created with SOLIDWORKS® software, and the steps required for our machinery to make the component are programmed offline. An Electronic Demand Profile (EDP), which is essentially a digital version of the bracket assembly, now exists and can be transmitted out to the machines on the shop floor.

After these steps are completed, the raw materials can be ordered and delivered to our Inbound Logistics Department, where they are inspected for conformance to the customer’s specifications.

STEP THREE: EXECUTION

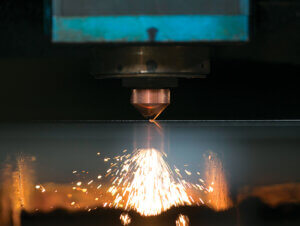

Laser Cutting

Utilizing the EDP, the order for the bracket assembly is first sent to our lasers, where the profile of the two pieces is cut out of the approved raw material. The part is nested with hundreds and thousands of other parts for the optimal yield out of each sheet. For reference, nesting is much like planning how many cookies can be cut out of one piece of dough.

Utilizing the EDP, the order for the bracket assembly is first sent to our lasers, where the profile of the two pieces is cut out of the approved raw material. The part is nested with hundreds and thousands of other parts for the optimal yield out of each sheet. For reference, nesting is much like planning how many cookies can be cut out of one piece of dough.

After each step, the bracket assembly goes to the Quality Department, where we use our 2D & 3D scanners to make sure everything lines up with the print. We create a distilled-down inspection criteria report for floor operators, which is called a Control Plan. So, when the part comes through again, it’s not a new part anymore. It’s now a production part. From this point on, the machine operators perform the quality control inspections. Quality doesn’t see the part again unless there’s an issue.

Press Brake Forming

Now it’s time to put the bend in the bracket assembly. Bends and forms are put into flat sheets of steel using a series of punches and dies. The brakes measure bending angles using specialized sensors, which relay real-time data to machine controls and adjust, if necessary, for enhanced forming accuracy.

Machining

Remember how the print for the bracket assembly showed indicators for tapped holes? This happens in our state-of-the-art CNC machining center. We utilize in-house CNC machining for a variety of reasons, but the main advantages are consistency, reliability and increased throughput. Tolerances are tested with a variety of measurement devices including micrometers, height gauges, indicators and CMMs (coordinate measuring machines).

Welding

After the metal components for the bracket assembly have been bulk cut on our laser machines, formed and machined, welding is used to connect the pieces together. Our welders are certified for almost any metal-to-metal welding job. For high-volume jobs, we have a Miller PerformArc 350S high output welding system (PA350S).

Finishing

The EDP then sends the bracket assembly to our Finishing Department for deburring, grinding and polishing. We can also arrange for specialized finishing procedures such as Blanchard grinding, zinc plating, black oxide and heat treating.

Powder Coating

Because there are threaded holes in the bracket assembly, a separate powder coating print will show where plugs are needed (to keep the paint out of the holes). Parts can be coated to any color our customers require on our 7-stage powder coating line. As the name implies, powder coating is applied to the bare metal as a free-flowing dry powder. The spray and metal surface are each given different electrical charges so that the spray is “magnetically” attracted to the metal and adheres to it. The piece is then sent into a cure oven (425 degrees for up to 30 minutes) to form a deep bond, or skin, on the metal. This electrostatic application creates a hard finish that is tougher than conventional paint.

Outbound Logistics

Finally, the completed bracket assemblies are packaged in the most economical fashion to ensure protection during transit. Packing slips are created to match the customer’s delivery timetable. Pickups are scheduled, the truck shows up, the containers are loaded onto the truck, it leaves the dock and the completed bracket assemblies are on their way.

Summary

The journey of a single bracket assembly is just one of the many thousands of parts we prepare for our customers on a daily basis. There are different steps, timetables and requirements based on the part, but on a universal level, we work hard at Laser Precision to maximize efficiency. It benefits us, and it benefits our customers.

Start to finish, this is a well-oiled process that helps us ensure stability in everything that we do. The result is time and money saved, and delivery of a high-quality part every time.

If you have a part you need fabricated, you now know what to expect. Contact us anytime to discuss the job at hand.