Selling Yourself Short Can Harm Long-Term Success

December 13, 2021

Things have been rough in the fabrication industry for the past 18-24 months. As supply chain issues increase, there is a huge temptation to cut corners to keep the shop busy and maintain income. For example, we recently bid on a project for a potential new customer who was moving a job from overseas due to the economic conditions. After a period of silence, we followed up and were told that our bid was 40% higher than the lowest offer. This seemed odd since our prices are usually within 10-15% of the market rate.

Wanting to make sure we were comparing apples to apples, we asked the prospect if we could walk through our bid together. What were we missing that was making us over-quote? Turns out, nothing. It was the lowest bidder that left something out. They were barely charging enough for the part to cover the cost of raw materials. If we hadn’t taken the opportunity to justify our bid, that potential customer would’ve thought we were just gouging them and ended up labeling us as a “high-cost supplier.”

Knowing Your Worth Builds Better Relationships

The “loss leader” method of doing business isn’t good for the fabrication shop or the customer. It can certainly get your foot in the door with a company you’ve never worked with before, but it’s definitely going to come back and bite you in the end.

How long can you reasonably sustain doing work that doesn’t generate a profit? What happens when the quality isn’t up to snuff? Can you make the delivery times they need? All of these elements are basically dominoes. You knock one down, and the rest will follow. The result is an unhappy customer and loss of the business.

Customer Priorities Are Always in Flux

A sound business model is still the key to success in the fabrication industry as we ride out the manufacturing trends that tend to come in waves and cycles. Overseas sourcing is a perfect example. For some years, the rationale was cost—the exploitation of low labor countries. But then, we learned that the offshore strategy sometimes sacrificed quality. And now, with today’s labor shortage and supply chain issues, the buzzword is “sustainability.”

Here are the three questions prospective customers are asking us today:

“Do you have any excess capacity?”

“Are you local?”

“Do you source your raw materials domestically?”

Proximity is a new realization. Borders do exist. Large manufactures are now placing a premium on having their suppliers closer to them. The goal is to streamline and compress the supply chain. It gives them more control over the value stream because they don’t have to worry about parts making it across the ocean.

Issues with the supply chain have created a lot of opportunities for stateside fabricators. But they must approach them in the right way. Instead of writing proposals “at cost,” it’s in their best interest to show new clients that they are worthy of a fair price. The total cost of ownership of a part has never been more relevant than it is today.

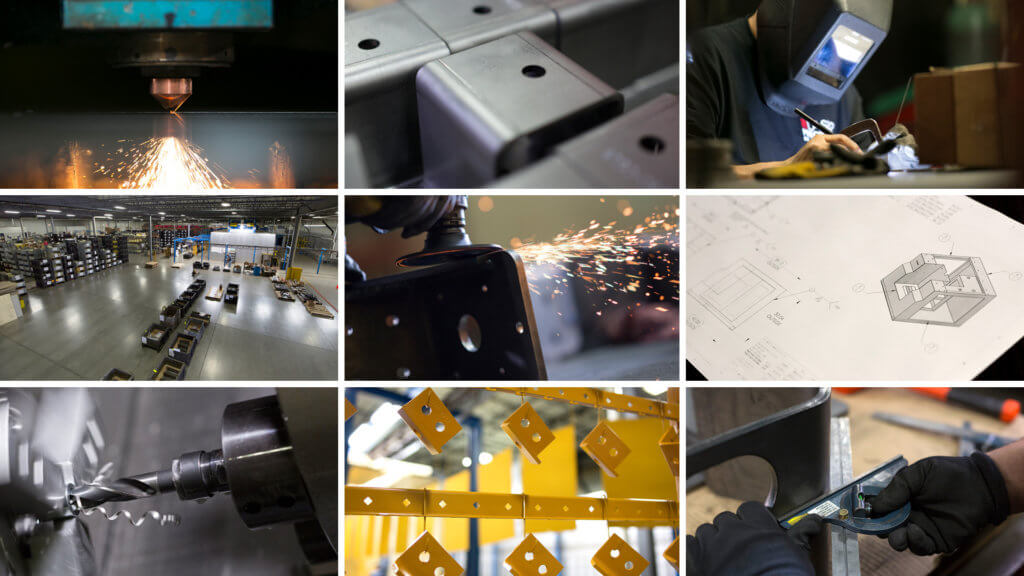

What Makes Laser Precision worthy?

What do we offer at Laser Precision to prove our worth?

Value. We believe we provide a fair market price for our products and services when customers look at the whole spectrum of our manufacturing process and offerings. Coupled with our on-time delivery and PPM (parts per million defect rate) performance, assurance of supply is worth it’s weight in gold.

- Laser Cutting

- Forming

- Machining

- Welding

- Assembly

- Finishing

- Powder Coating

- Engineering Support

- Logistics

Quality. Quality is measured by the number of defective parts per million shipped (ppm). Our record is better today than at any time in our history. Our current average is at 50/60 ppm. In other words, we ship less than 60 defective parts for every 1,000,000 that we ship.

On-Time Delivery. We’re entrusted to work with some of the largest OEMs in the world. Despite the supply chain headwinds the industry has faced, we’re still close to 100% in on-time delivery. They know that they can only assemble their machines as fast as their slowest supplier, so they look to supply partners with minimal kinks in their production process.

Continuous Improvement. This is something as simple as having 5S programs in place, ways for employees to speak up about improving certain processes, and investments in new capital equipment to add and expand more in-house capability.

Support. We have knowledgeable in-house engineers familiar with part design for cost and manufacturability. We’re able to ask a customer, “Have you considered making your part this way instead?” We’re often invited to our customers’ facilities to look at the parts they require for their equipment. Almost every time, we can point out ways we could improve the processes.

Knowing the worth of your fabrication company and the products it makes isn’t just important for your own bottom line. It’s imperative for your customers as well. Onboarding a new supplier is a huge undertaking for companies. It requires personnel to start shopping those existing parts to new suppliers, and it’s a burdensome thing for them to do. It can take months to onboard a supplier.

Long-term sustainability has recently taken on a new meaning for many manufacturers. One of the reasons our customers trust us is because they know, during good times and bad, the products we produce are of high value, excellent quality and delivered on time. That makes for mutually beneficial partnerships that are worth every ounce of effort and every dollar we spend on maintaining them.