The ABCs of Metal Fabrication

November 14, 2022

The ABCs of Metal Fabrication

Looking for a career change? Manufacturing is a great opportunity. At Laser Precision, it doesn’t really matter what you’re doing now. Many of our employees started with little to no fabrication experience. That’s okay. We always try to hire self-starters and train them on the job.

As you start putting your résumé together, we thought it might be beneficial to provide a look at some of the most common metal fabrication terms. Like any industry, there are many acronyms in the business that can be mystifying to the beginner. Here’s a look at some of the ones you might hear during your interview and on the shop floor.

AWS: American Welding Society

Lots of people now know this as Amazon Web Services, but around here, AWS describes a far more longstanding acronym: the American Welding Society. Every one of our welders is certified by the AWS, not only on their general skill and knowledge, but for every type of weld they make! This ensures they produce high-quality production welds day in and day out.

CNC: Computer Numerical Control

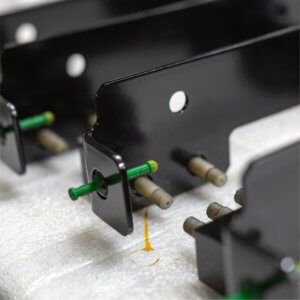

A machine tool forms or cuts metal and other materials by bending, milling, drilling, grinding or other methods. CNC machine tools are controlled by a computer without a manual operator directly controlling the machining operation. CNC machining quite literally keeps the world moving, and it has been a vital element of our success since we opened for business.

CI: Continuous Improvement

A never-ending effort to improve equipment and processes to provide maximum value to customers and reduce unproductive activities. As economic environments fluctuate, we will always make improvements to our equipment and processes. It’s just good business.

ERP: Enterprise Resource Planning

Software that an organization can use to collect, store, manage and interpret data from many business activities. In other words, an ERP lets us capture all the data about a specific part plus all the operations (laser cutting, forming, welding, etc.), materials and actions needed to fabricate the piece. Anything anyone needs to know about the job is right there.

ISO: International Standards Organization

ISO stands for International Organization for Standardization (Not actually an acronym. It’s taken from the Greek word “isos”, meaning equal), which develops global standards for different industries. All ISO standards are reviewed every five years to keep them current and relevant for the marketplace. Laser Precision was recently recertified for ISO 9001:2015, the most recent standards update.

MIG: Metal Inert Gas

Most of our welding work is done with the MIG method, in which an electric arc (kind of like a mini lightning bolt) forms between a consumable wire electrode and the workpiece metal. This heats the workpiece metal, causing the pieces to melt and join. This gives a high-quality, structurally sound weld.

OTD: On-Time Delivery

On time delivery is the ratio of finish goods or shipments delivered on time to customers as a percentage of total units delivered or shipped. Laser Precision has a 92% OTD across 3,000 shipments per month.

PPM: Parts Per Million

In manufacturing, PPM represents the number of defective units per 1 million units. Laser Precision’s PPM is currently 116. In other words, only 116 parts out of every one million (or one part out of every 8,620) are unacceptable.

QC: Quality Control

You’ll hear this one a lot at Laser Precision. It’s how we achieve 116 PPM. We define quality as: “Meeting any and all customer expectations and requirements.” We document it, constantly measure it and continually improve it. As a result, our quality record is better today than any time in our history.

RFQ: Request for Quote

An RFQ is a document that details pricing options for a specific service or product. We make sure all the information that is needed for the project has been documented before the quote is submitted. We ask questions and never assume. This care minimizes price changes due to additional processes missed at the RFQ stage, and negative impacts to delivery times as well.

All these terms may seem confusing at first, but once you take your place on the shop floor, we’ll provide the TLC that will help you start using them PDQ.

If you are thinking about a career in manufacturing and would like to learn more, please contact us. We’ll get back to you ASAP.